3D Printing Space

About

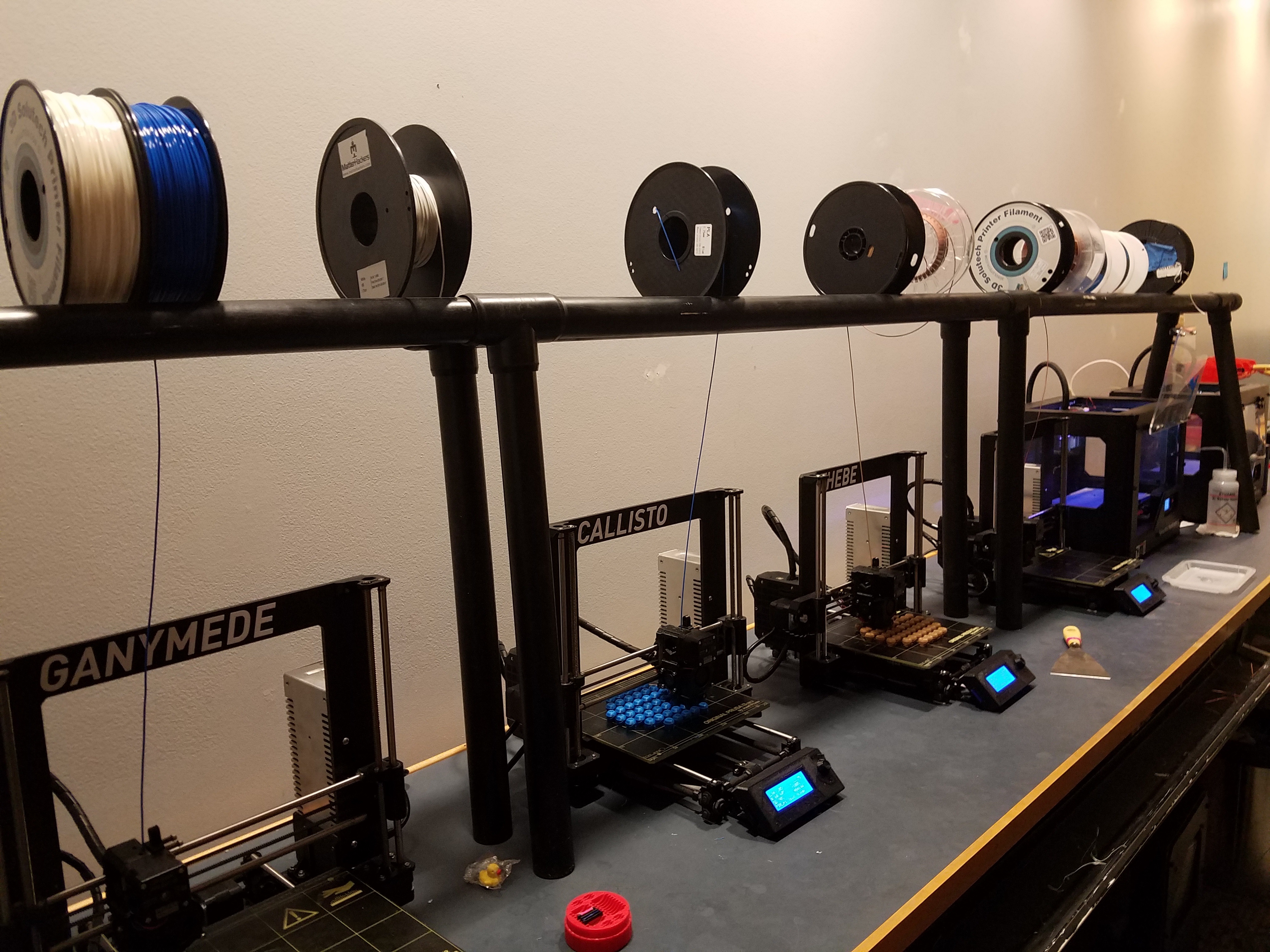

As manager of the 3D printing space at Olin College of Engineering it is my job to maintain the printers and the space to ensure usability and safety. This means fixing any broken printers, training both students and staff of the college on how to use the printers, help fellow students with projects involving CAD and 3D printing, as well as implementing improvements to the space to help with these endevours. Over the past three years of upkeeping the space, more than 65% of the student population has been trained to use the printers. In addition to training the community, part of my responsibilities also include reaching out through various events. Each Halloween a 3D scanning event is held for those who want to later print themselves in costume. Through the use Slack, problems that arise can be quickly brought to attention and resolved, as well as providing a quick and easy way to answer any questions about printing when I am not directly in the space. In winter of 2017 Replay 3D, a Boston based PLA recycling startup, became a partner of the space, helping align with Olin's and my personal goal of being more eco-conscious. In fall of 2018 the space expanded as part of the college's machine shop to include SLA resin printers. Due to the potentially hazardous nature of the resin, additional safety and training was implemented. The space is currently host to 10 printers: 5 Prusa i3 Mk2s (one of which is a multimaterial unit), 2 Pursa i3 Mk3s, a mUVe 1 SLA printer and 2 Autodesk Ember SLA printers.

Skills

- 3D Printing - Knowledge of and how to effectively apply it to improve the space. Maintain and repair FDM and SLA printers throughout the school year. Help other students with their projects.

- Solidworks - Design parts for improvement of the space. Help other students with their projects and how to optimize for 3D printing.

- Community Outreach - Interact with over 65% of the Olin Community to create a successful and welcoming environment. Done through Slack and various media communications including in person trainings, posters, banners, and polls.

Team

- Amy Phung - Fellow student manager

3D Printing Shelf in Olin's Library

Resin Printing Shelf in Olin's Machine Shop